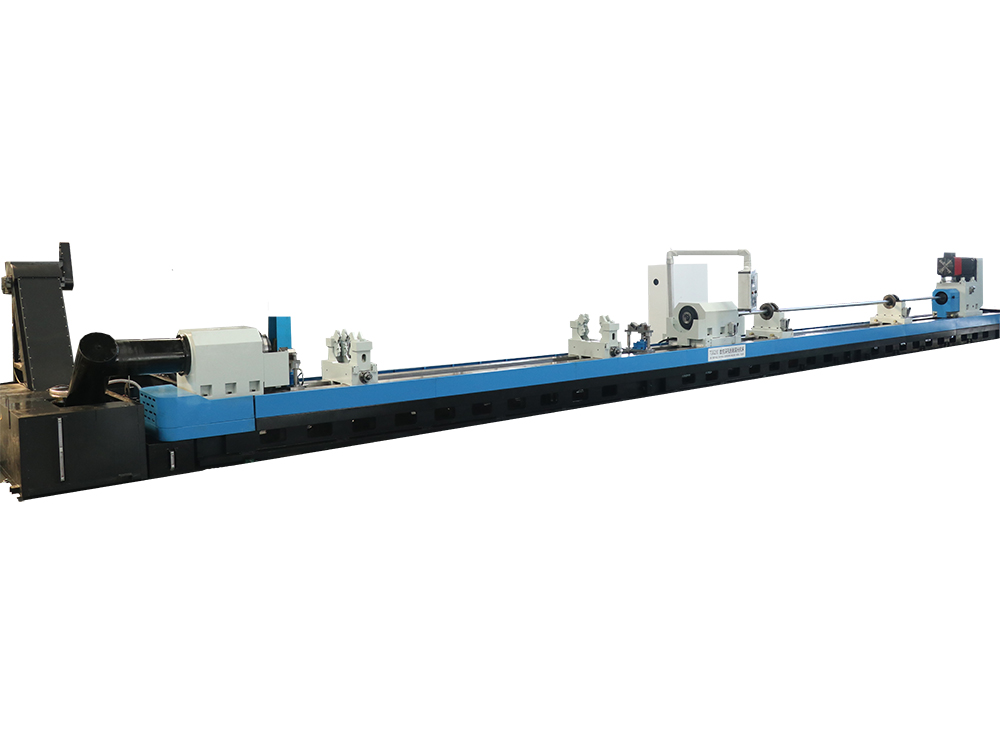

Deep Hole Skiving Roller Burnishing Machine

Features:

TGG/TGK deep hole skiving roller burnishing machine.

TGG/TGK deep hole skiving roller burnishing machine is the substitution for deep hole boring machine, combined the rough boring and precision boring, utilize the pushboring to finish the rough and precision boring processing while utilize the retract to finish the rolling process, so this machine hasthe following advantages: High efficientsave processes. Traditional process have to use 2-5 processes, but this machine can do the work one process.

High accuracy, one time process can achieve IT8, surface roughness is up to Ra0.05-Ra0.4um.

Enhance the surface hardness, finished workpiece surface hardness increase more than 50%. Working environment: low noise, no pollution, save labors.

Main Technical Specifications and Performance

| Item Name | Parameter | |||||

| Machine Model | TGK200 | TGK250 | TGK320 | TGK400 | TGK500 | |

| Workpiece Dimension | Inner Hole(mm) | 38-200 | 38-250 | 100-320 | 160-400 | 200-500 |

| Outer Hole(mm) | 45-250 | 45-300 | 120-380 | 200-500 | 250-650 | |

| Working Length | 500-L* | 500-L* | 600-L* | 600-L* | 600-L* | |

| Speed | Spindle Speed(r/min) | 200~1200 | 1600~1000 | 125~800 | 100~630 | 80~500 |

| Osition Holder Move(mm/min) | 1500 | 1500 | 0-2000 | 0-2000 | 0-2000 | |

| Spindle Box Move(mm/min) | 0-3000 | 0-3000 | 0-3000 | 0-3000 | 0-3000 | |

| Motorpower | Spindle Motor(kW) | 30/70 | 37/45 | 60 | 75 | 90 |

| Infeed Servo(kW) | 4.4 | 4.4 | 7.5 | 7.5 | 7.5 | |

| Coolantsystem | Oil Box Volume (L) | 3200+1850 | 3200+1850 | 6000+2100 | 6000+2100 | 6000+2100 |

| Pump Flow (L/min) | 600 | 600 | 800 | 1000 | 1200 | |

| Filtering Accuracy (um) | 30 | |||||

| Motor Total Power (kW) | 80 | 100 | 120 | 160 | 200 | |

| CNC System | SIEMENS/ KND | |||||

Welcome to send your message to us