BTA Deep Hole Drilling Machine

Deep hole boring and scraping series:

Our deep hole boring machine, adopts BTA processing method, can drill, bore and rolling. The processing accuracy as below. Drilling: hole accuracy IT9-IT11, roughness Ra3.2um-12.5um.

Rough boring: hole accuracy IT8-IT9, roughness Ra3.2-Ra6.3um

Precision boring: hole accuracy IT7-IT9, roughness Ra1.6-Ra3.2um

Rolling: hole accuracy IT6-IT7, roughness Ra0.4-RaO.8um.

Hole linear less than 0.5mm/1000mm

Drilling hole diameter range:30mm to 120mm Boring hole diameter range:40mm to 1000mm Hole depth: up to 15000mm.

According to customers requirement, workpiece shape and processing requirement, we can design accordingly.

Application fields: all kinds of mechanical hydraulic cylinders. Processing lathe spindle holes, pnumatic pillar holesspecal oil cylinder, coal cylinder, high pressure boiler tube, peture and military fields.

Our skiving roller burnishing machine is manufactured basing on the adopting advanced technology of competitors, according to ourself experience. The machine advantage is: processing speed is nearly 20 times than the traditional honing process. Surface hardness increase more than 50%, processing accuracy up to IT8, surface roughness up to Ra0.05 to Ra0.4um.

Application: all kinds of hydraulic cylinder, air cylinders inner hole high accuracy processing.

Mainly products of this series: T21 deep hole drilling & boring machines.

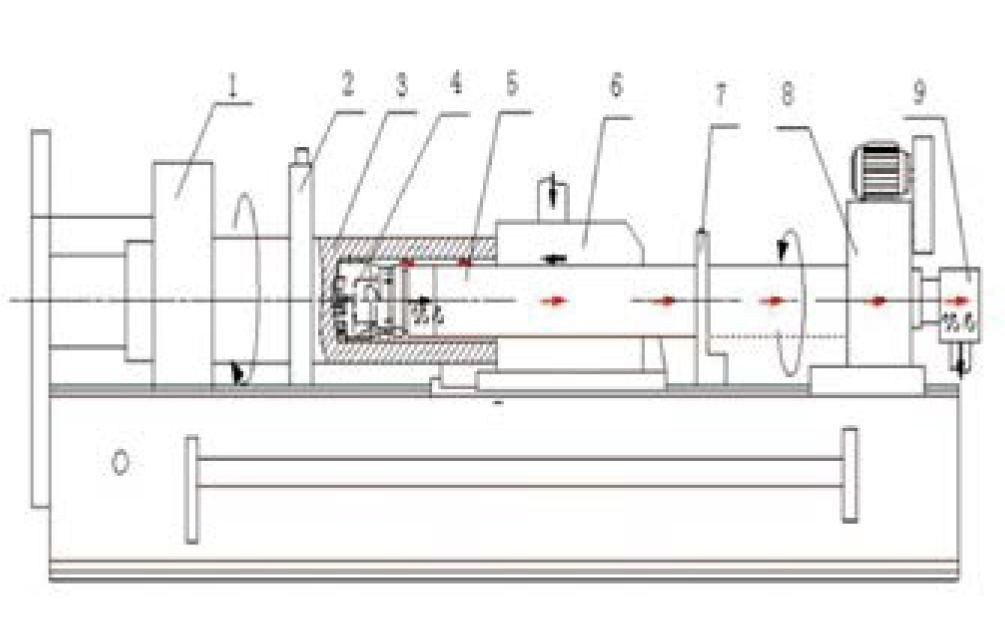

Sketch Map

-

Schematic processing:

1. spindle box

2. central box

3. workpiece

4. cutter

5. drilling bar

6. oil supply device

7. drilling bar support frest

8. drilling bar box

9. chips removal device

-

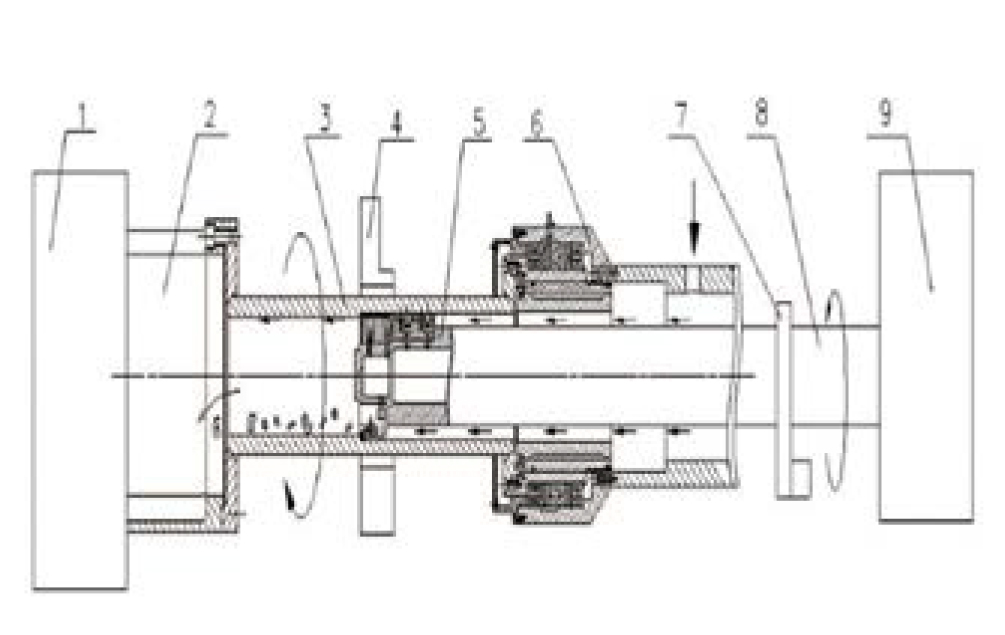

Boring processing schematic:

1. spindle box

2. chunk

3. workpiece

4. center rest

5. boring head (cutter)

6. oil supply device

7. drilling bar support rest

8. boring bar

9. boring bar box

-

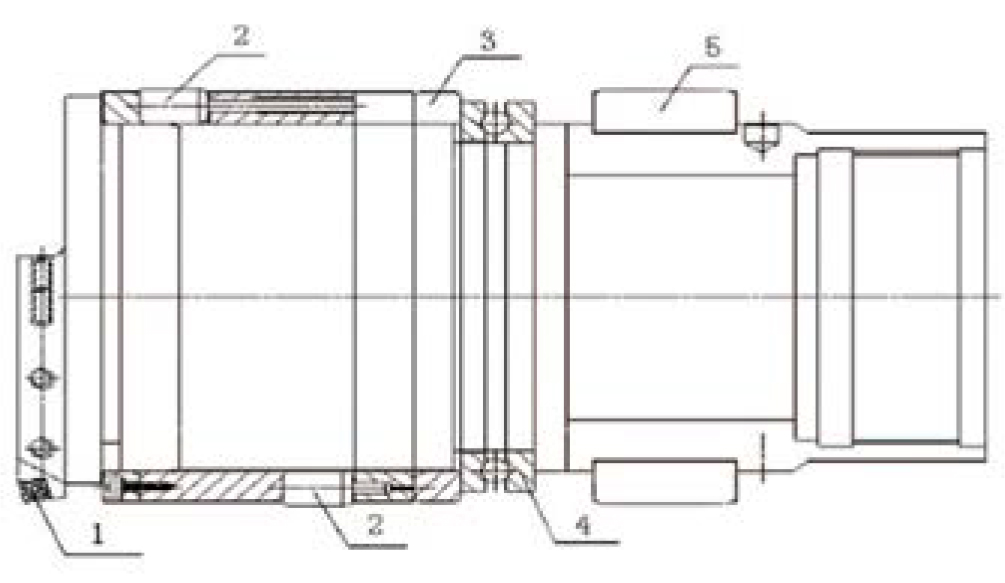

TGG boring & rolling head:

1. Insert

2. ball

3. replace ring

4. bearing

5. guide pad

-

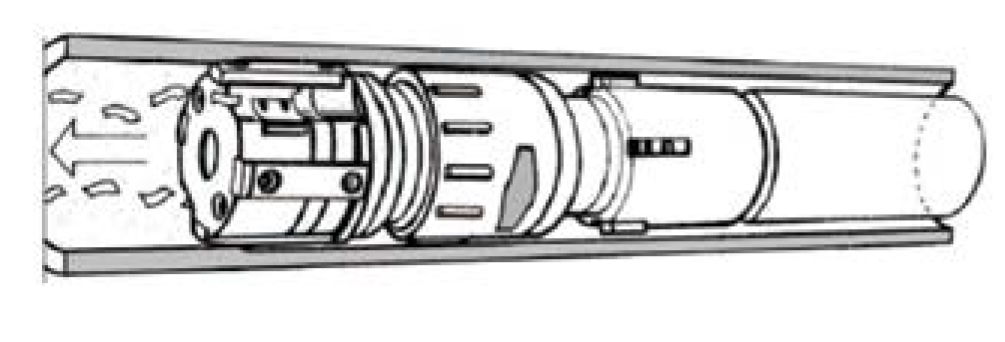

Skiving & Burning Cutter:

The scraping and rolling automatic expansion and contraction combination tool is suitable for batch production of precision cold drawn pipes, as well as mass production of other types of steel pipes after rough machining. With a diameter margin of 1mm, the feed speed can reach 50Omm~1250mm per minute, the roundness can reach 0.01m, and the roughness is not greater than Ra0.4m. The inner core rod of the boring bar can be controlled by hydraulic pressure to automatically shrink the scraping blade block and roller, ensuring the stability of deep hole processing and greatly improving processing efficiency.

Welcome to send your message to us