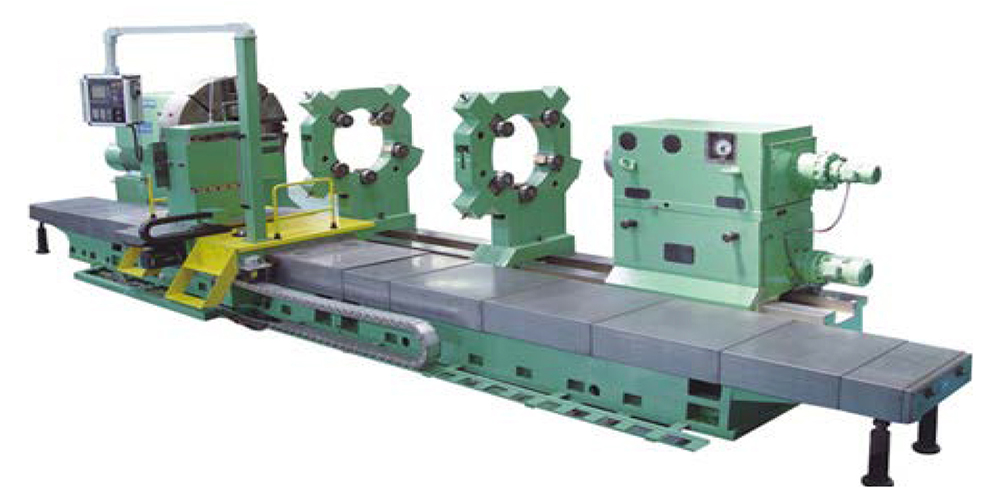

CK611-F Series CNC Heavy Duty Lathe

Features:

This series of heavy-duty horizontal lathes fully absorbs the international contemporary advanced technology, adopts the international advanced design methods and manufacturing technologies, such as three-dimensional modeling, simulation design, finite element analysis, etc. It is a mechatronic machine tool product integrating multi-disciplinary and multi-category precision manufacturing technologies such as electrical, automatic control, hydraulic control and modern mechanical design.

This series of machine tools has excellent structural performance. The machine tools have the characteristics of high dynamic and static rigidity, long service life, high processing efficiency, safe and reliable functions, convenient operation and beautiful appearance.

1. The main shaft of the spindle box is a through-shaft structure, and the main shaft is supported by highprecision double-row cylindrical roller bearings, with high precision and good stability.

2. The main drive is driven by AC spindle servo motor or DC motor, with two mechanical gears, stepless speed regulation within the gear, wide speed regulation range and good adaptability.

3. The guide rail of the bed adopts the overall three guide rails or the whole four guide rails, and adopts the fine grinding processing method. The main guide rail surface of the bed adopts the intermediate frequency quenching treatment, and the hardness can reach HRC50.

4. The tailstock is of upper and lower split structure, and the mandrel in the sleeve adopts double row short cylindrical roller bearings with high precision and adjustable radial clearance; the movement of the sleeve and tailstock is motorized and equipped with a force measuring device.

5. The tool holder adopts ball screw horizontally, and adopts high-precision rack and double-toothed rod backlash-elimination structure vertically, which improves the transmission accuracy of the tool holder.

6. The machine tool is equipped with a walking platform and a hanging button station, which is easy to operate.

7. The range and quantity of open and closed steady rests can be configured according to user requirements.

8. This series of machine tools adopts Siemens 828D system . Other CNC systems can also be selected by the user.

9. Double tool rests, milling and boring devices, grinding devices, iron chip conveyors, tool cooling systems, etc. can be provided according to user requirements.

Notice: boring, milling, grinding, drilling functions are optional.

Main Technical Specifications and Performance

| Item | Machine model | |||

| CK61125F | CK61160F | CK61200F | CK61250F | |

| Max.swing diameter over bed | 1250mm | 1600mm | 2000mm | 2500mm |

| Max.swing diameter over turret | 1000mm | 1250mm | 1600mm | 2000mm |

| Max.workpiece length between two centers | 4-20mm | 4-20mm | 4-20mm | 4-20mm |

| Max. workpiece machining weight between two centers | 40T | |||

| Machine guide rail type | Integral three-guide rail or integral four guide-rail | |||

| Machine bed guide rail width | 1615mm | 1615mm | 1850mm | 2050mm |

| Disc diameter | 1250mm | 1600mm | 1600mm | 2000mm |

| Spindle rotary speed range | 0.8-160r/Min | 0.8-160r/Min | 0.8-160r/Min | 0.8-160r/Min |

| Spindle gear speed | Mechanical two gears, stepless in the gear | |||

| Tailstock sleeve stroke | 300mm | |||

| Turret type | Frame type turret, vertical four-station electric turret, vertical fourstation manual turret | |||

| Turret infeed amount range | 0.1-1000mm/min | |||

| Turret rapid traverse rate | 4000mm/min | |||

| Turret feed stage | Stepless | |||

| Main motor power | 75kW/90kW | |||

| CNC system | Siemens 828D or other CNC control system | |||

Welcome to send your message to us