BTA Deep Hole Drilling Machine

We have the following models:

T2120, max boring hole is 200mm, job Length is up to 30m.

T2125, max boring hole is 250mm, job length is up to 30m.

T2135, max boring hole is 350mm, job length is up to 30m.

T2150, max boring hole is 500mm, job length is up to 30m.

T2180, max boring hole is 800mm, job length is up to 30m.

T21100, max boring hole is 1000mm, job length is up to 30m.

T21200, max boring hole is 2000mm, job length is up to 30m.

BTA deep hole drilling machine function:

Solid drilling, counter boring, pull boring, trepanning, burnishing.

BTA deep hole drilling processing method:

Job can rotate, tool fixed.

Job can fixed, tool rotate.

Job can rotate, tool rotate as well.

We have the following customized BTA deep hole drilling machine for your reference:

BTA deep hole drilling and gun drilling combined machine,two drilling system could be used in one machine, working ID diameter range could be from 20mm to 100mm.

Twin hole BTA deep hole drilling machine, specially for twin screw barrels, eight shape hole.

High speed deep hole boring machine, special structure and could make fast boring process, about 400mm/min infeeding.

Through type deep hole drilling machine, specially for drill collar industry.

Deep hole trepanning machine, specially for expensive material to get core, which has much values than chips.

Deep hole pull boring machine, special design deep hole pull boring machine, which could get good drift tolerance.

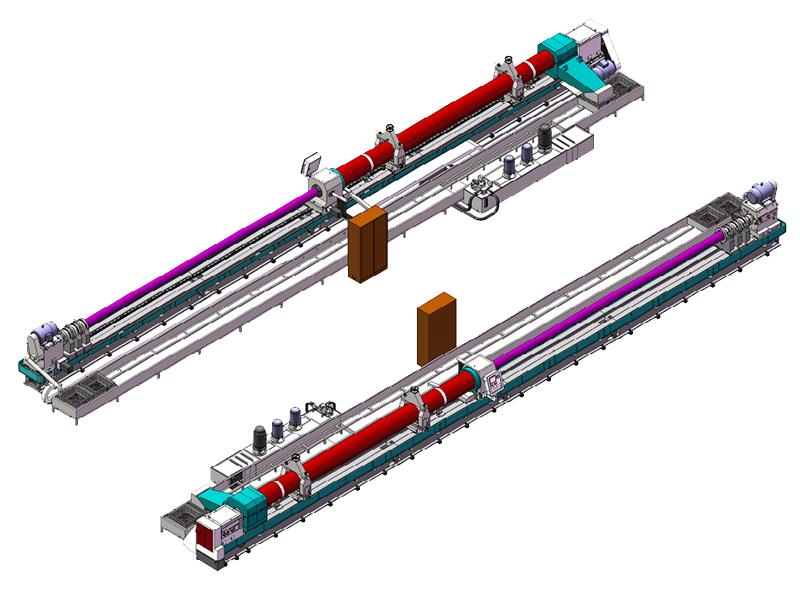

Please see our mainly structure of standard deep hole drilling machine:

Machine main components:machine bed, headstock, oil pressure head, drill bar support rest, drill box, slide rail, rack and pinion, coolant system, PLC(or CNC) control system, electric box, center rest.

Machine bed: Cast by gray iron HT300 (casting material report is available), after cast, the machine bed will experience tempering and quenching process to eliminate the internal stress, double rectangular guide rail, which surface hardness is 48-52HRC, transmission system is rack and pinion, the rack could use straight gear or helical gear. Machine bed box is triangle and inclined ribs are inside. Apron type protection is installed around the bed.

Headstock: 12 stage manual speed control. The gear is precisely ground, surface hardness could be HRC48-52, headstock has lubricating system.

Center rest: Three-point closed center rest structure has two rollers on the bottom and one roller on the top;

Oil pressure head: The oil pressure head has servo motor to drive the head to tighten or loosen the workpiece, and infeeding.

Drill box: 12 stage manual speed control. The gear is precisely ground, surface hardness could be HRC48-52, headstock has lubricating system.

Brill bar support rest: It will absorb the vibration during machine working.

Workpiece clamping:One side is manual three-jaw chuck, the other side could be chuck or coned disc.

Machine control system: FANUC /Siemens or PLC

Coolant system: It is mainly composed of a cooling pump, a chip receiving box, an oil tank, etc., to provide sufficient cutting oil for deep hole processing.

Welcome to send your message to us