Skiving Roller Burnishing Machine

We have the following models:

TGK200, SRB hole range is 38mm-200mm, job length is up to 9m.

TGK250, SRB hole range is 38mm-250mm, job length is up to 9m.

TGK320, SRB hole range is 40mm-320mm, job length is up to 9m.

TGK400, SRB hole range is 40mm-400mm, job length is up to 9m.

TGK500, SRB hole range is 40mm-500mm, job lenght is up to 9m.

SRB function:

The machine is specialized for hydraulic cylinder industry. One time processing, the forward process is for skiving, the backward process is for burnishing process.

Also we have combined SRB machine, which could boring also, SRB function combined. It is applicable for big cutting volume jobs, by using boring head first, then use SRB head to get good surface.

SRB processing method:

Job can fixed, tool rotate.

Job can rotate, tool rotate as well.

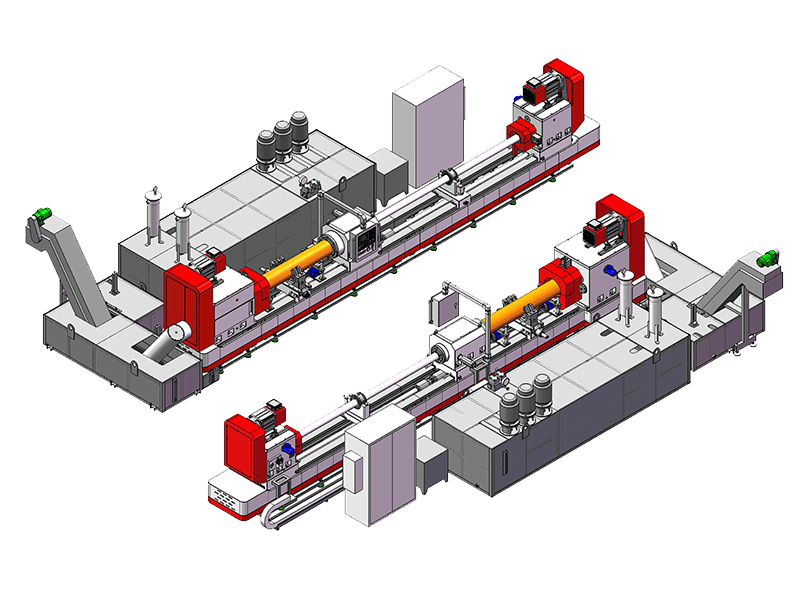

We have the following customized SRB machine for your reference:

Heavy duty SRB machine, which could have bigger cutting volume.

Boring and SRB machine combined machine, the machine could boring and SRB, it is for big cutting volume jobs.

SRB machine with auto loading and unloading system, which will reduce labour work and operate easily.

Please see our mainly structure of standard SRB machine:

Machine bed, head frame, workpiece carrier, self-centering clamping device, oil pressure head, boring box, boring bar support rest, feeding system, cooling system, CNC control system and so on.

Machine bed: Cast by gray iron HT300 (casting material report is available), after cast, the machine bed will experience tempering and quenching process to eliminate the internal stress, double rectangular guide rail, which surface hardness is 48-52HRC, transmission system is ball screw. Trapezoidal screw is used for self-locking the oil pressure head.

Head frame: Hydraulic system to drive the spindle to tighten the workpiece. Cone disc and guide sleeve are on the headstock, also chips bin is there.

Workpiece carrier and hydraulic clamping device: Workpiece carrier helps to load the workpiece, while hydraulic clamping device is used for clamping the workpiece.

Oil pressure head: It is core part of the machine, cone disc mounting on the pil pressure head to position and tighten the workpiece. It is powered by a trapezoidal screw pair.

Boring box: It is driving the SRB tool to rotate and infeed. The bearing of boring box is well lubricated.

Boring bar support rest: It is used to support the boring bar. It can absorb the vibration during machine working.

Coolant system: Oil tank is on the ground. Cooling oil take away the cutting chips and then filtered through filters.

Hydraulic system: It supply hydraulic power to workpiece tightening, workpiece clamping, oil pressure locking, automatic tool expansion and contraction.

Control system: Siemens/Fanuc/GSK

Welcome to send your message to us