Tongyuan Brand CNC Heavy Duty Lathe

Models available for CNC heavy lathe:

CK61125T, CK61140T, CK61180T, CK61200T

Max loading capacity: 25T

Max bed width: 1100mm.

CK61125F, CK61160F, CK61200F, CK61250F

Max loading capacity: 40Ton

Max bed width: Integral three guide rails or four guide rails.

CNC heavy duty lathe machine function:

Turning function, is suitable for processing shaft, sleeve and disc parts.

Drilling funcion

The turning milling machine is a machine tool with B-axis linkage and C-axis linkage that can do turning and milling. It can be said that the turn milling machine can complete all or most of the processing of a part, so it is also called a small production line. It can not only improve the accuracy of products and the efficiency of processing products, but also greatly save the floor area of the machine tool for enterprises, In the past, it was necessary to finish the processing of one part on several machine tools, but now only one machine can finish all the processing.

CNC turning milling machine can meet the functions of turning, milling, drilling, grinding, etc. The milling function with small processing volume can be completed with power turret, the milling function with large processing volume can be installed with milling attachment, the special milling head box can achieve large milling volume. The installation of attachments sometimes affects the main cutting parameters of the machine tool, such as cutting diameter, vertical and horizontal travel, etc. So customer should be aware of this points.

CNC turning milling machines are widely used in renewable energy, rail transit, steam turbines, oil and gas equipment, roll industry and general industry. Customers who has the demand are welcomed to put forward requirements before ordering the machine, and we will provide you with the best solutions.

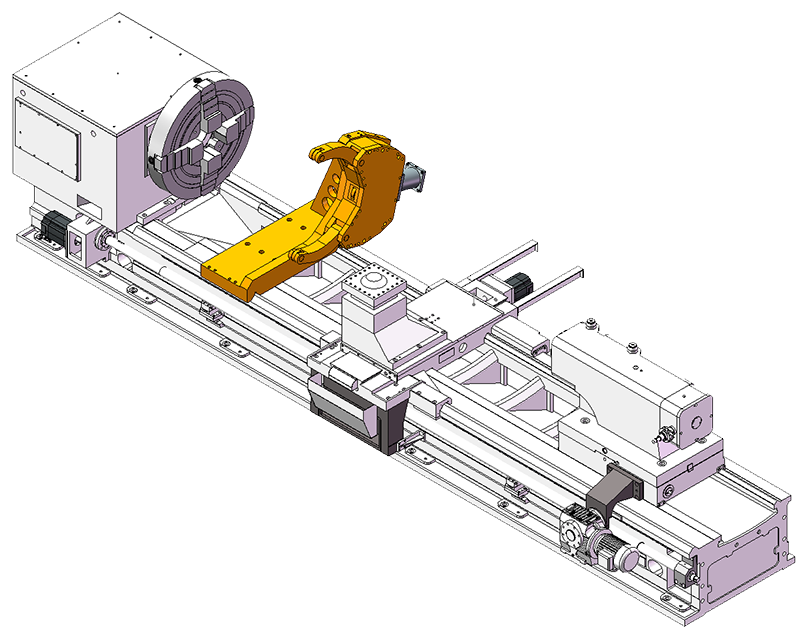

Heavy lathe mainly parts:

Machine bed: Casted by iron, Integral three guide or four guide rail. Guide rail will be quenched, hardness is not less than HRC50. Double rectangle structure.

Main spindle box: Has independent hydraulic control system and lubrication system. Driven by AC main spindle servo motor, When install the workpeice, machine has heavy duty chuck and mechanical.

Tool turret: The tool turret is composed of a carriage and power turret.

Tailstock: Aopts up and down split structure. Tailbox and tail box sleeves rapid move are drag by independent motor. And have overloading protector.

Auto lubricating system and Hydraulic system:

Machine all parts have independent lubrication system, hydraulic system has two parts, headstock hydraulic system and tailbox hydraulic system.

Center rest:

The machine is equipped with center frame. Open type or crescent moon type

Auto chips conveyor and coolant system:

The machine is equipped with chain plate auto chips conveyor, integrated water tank and cooling pump. The chips conveyor is installed at the back of the machine. The cooling pump sends cooling water to the tool turret through pipes.

CNC control: Siemens/Fanuc/Chinese brand CNC

Welcome to send your message to us